The Occupational Safety and Health Administration (OSHA) keeps records not only of the most frequently cited standards overall, but also within particular industries. The most recent statistics from OSHA reveal the top standards cited in the fiscal year 201X for the construction industry. This top 10 list comprises establishments engaged in the construction of buildings or engineering projects (e.g., highways and utility systems). Establishments primarily engaged in the preparation of sites for new construction and establishments primarily engaged in subdividing land for sale as building sites are also included in this sector.

| Description of Violation | Cited Standard Number | ACV* |

| Duty to Have Fall Protection – Complying with the OSHA requirements for fall protection systems that conform with all requirements for quality, quantity and safety. | 29 CFR 1926.501 | $2,829 |

| General Scaffold Requirements – Using and maintaining scaffolds or related equipment properly according to manufacturer’s standards. | 29 CFR 1926.451 | $1,785 |

| Ladders – Proper use and maintenance of all ladders on site according to the OSHA standards of support, construction, protection, proper use and employee awareness. | 29 CFR 1926.1053 | $1,484 |

| Training Requirements – Providing mandatory training for all employees who may be exposed to fall hazards that allows workers to recognize and react to exposures. | 29 CFR 1926.503 | $991 |

| Eye and Face Protection – Ensuring employees use appropriate eye/face protection when exposed to hazards from flying particles and harmful vapors or rays. | 29 CFR 1926.102 | $1,502 |

| Head Protection – Providing employees with head protection that meets ANSI specifications when they work in areas where there is a possible threat of head injury. | 29 CFR 1926.100 | $1,450 |

| Hazard Communication – Properly transmitting information on chemical hazards through a comprehensive program, container labeling, SDS and training. | 29 CFR 1910.1200 | $397 |

| General Safety and Health Provisions – Ensuring that no employee or anyone who is a part of contract work has to perform any duties under unsanitary or hazardous conditions. | 29 CFR 1926.20 | $1,324 |

| Aerial Lifts – Following OSHA’s general requirements for aerial lifts, which include proper design, construction, operation, precautions and use. | 29 CFR 1926.453 | $1,915 |

| Specific Excavation Requirements – Proper guarding of surface encumbrances, marking of all underground utility lines, safe means of entrance and egress and effective protection from falling material. | 29 CFR 1926.651 | $2,389 |

*ACV (Average Cost per Violation) – The dollar amount represents the average cost per violation that employers in this industry paid in 2014. To understand the full capacity and scope of each standard, click on the standard number to visit www.osha.gov and view the language in its entirety. Source: OSHA.gov

OSHA Rule for Residential Fall Safety

The Occupational Safety and Health Administration (OSHA) has issued some guidance on fall protection for residential construction employers. OSHA Directive STD 03-11-002, withdraws a former directive allowing residential builders to bypass fall protection requirements.

The directive:

- Requires all residential construction employers to comply with the OSHA rules for fall protection systems;

- Provides that employers must prove that the use of conventional fall protection methods is infeasible or creates a greater hazard before using alternative fall protection methods; and

- Clarifies the definition of residential construction

OVERVIEW OF THE RESIDENTIAL FALL SAFETY RULES

Under Directive STD 03-11-002, all residential construction employers must comply with the fall protection requirements found in29 CFR 1926.501(b)(13). In general, this section states that residential construction employers must ensure that employees working at least six feet above lower levels use guardrails, safety nets or personal fall arrest systems.

A personal fall arrest system is defined in 29 CFR 1926.500. It may consist of a full body harness, a deceleration device, a lanyard and an anchor point. An effective fall restraint system may be used in lieu of a personal fall arrest system. A fall restraint system iseffective if it is rigged to prevent a worker from reaching a fall hazard and falling over the edge. A fall restraint system may consist of a full-body harness that is connected to an anchor point at the center of a roof by a lanyard of a length that will not allow a worker to physically reach the edge of the roof.

Other fall protection measures may be used if they are allowed under other provisions of 29 CFR 1926.501(b) that address specific types of work. For example, section (b)(10) permits the use of warning lines and safety monitoring systems during the performance of roofing work on low-sloped roofs.

An employer does not have to use these conventional fall protection methods if it can demonstrate that their use is infeasible or creates a greater hazard. However, the employer must ensure that a qualified person creates a written, site-specific fall protection plan that complies with 29 CFR 1926.502(k). The fall protection plan must document the reasons that conventional fall protection systems are infeasible or their use would create a greater hazard.

Prior Interim Guidance

After the residential construction fall protection standard was originally issued in 1995, representatives of the residential construction industry argued that they needed more flexibility than the standard allowed. These requests led to interim guidance in the form of Directive STD 03-00-001, which allowed residential construction employers to use certain alternative methods of fall protection, such as slide guards or safety monitor systems, rather than the conventional methods required by the standard.

Under the interim directive, employers could use the alternative methods without first proving that the use of conventional fall protection was infeasible or created a greater hazard and without a written fall protection plan.

Brought to you by:

Associates Insurance Agency

Construction Employee Safety Manual

Brenman Company

An Employee Guide to Safety Policies and Procedures

to Support a Safety-Conscious Work Environment

Provided by: Associates Insurance Agency

Legal disclaimer to users of this form employee handbook:

The materials presented herein are for general reference only. Federal, state and/or local laws, or individual circumstances, may require the addition of policies, amendment of individual policies, and/or the entire Handbook to meet specific situations. These materials are intended to be used only as guides and should not be used, adopted, or modified without the advice of legal counsel. These materials are presented, therefore, with the understanding that the Company is not engaged in rendering legal, accounting, or other professional service. If legal advice or other expert assistance is required, the services of a competent professional should be sought. © 2008-2012 Zywave, Inc. All rights reserved.

Commitment to Safety

Brenman Company recognizes that our people drive the business. As our most critical resource, employees will be safeguarded through training, provision of appropriate work surroundings, and procedures that foster protection of health and safety. All work conducted by Brenman Company’s employees will take into account the intent of this policy. No duty, no matter what its perceived result, will be deemed more important than employee health and safety.

Brenman Company is firmly committed to the safety of our employees. We will do everything possible to prevent workplace accidents and we are committed to providing a safe working environment for all employees.

We value our employees not only as employees but also as human beings critical to the success of their family, the local community, and Brenman Company.

Employees are encouraged to report any unsafe work practices or safety hazards encountered on the job. All accidents/incidents (no matter how slight) are to be immediately reported to the supervisor on duty.

A key factor in implementing this policy will be the strict compliance to all applicable federal, state, local, and Company policies and procedures. Failure to comply with these policies may result in disciplinary actions.

Respecting this, Brenman Company will make every reasonable effort to provide a safe and healthful workplace that is free from any recognized or known potential hazards. Additionally, Brenman Company subscribes to these principles:

- All accidents are preventable through implementation of effective Safety and Health Control policies and programs.

- Safety and Health controls are a major part of our work every day.

- Accident prevention is good business. It minimizes human suffering, promotes better working conditions for everyone, holds Brenman Company in higher regard with customers and increases productivity. This is why we will comply with all safety and health regulations that apply to the course and scope of operations.

- Management is responsible for providing the safest possible workplace for Employees. Consequently, management of Brenman Company is committed to allocating and providing all of the resources needed to promote and effectively implement this safety policy.

- Employees are responsible for following safe work practices and company rules, and for preventing accidents and injuries. Management will establish lines of communication to solicit and receive comments, information, suggestions and assistance from employees where safety and health are concerned.

- Management and supervisors of Brenman Company will set an exemplary example with good attitudes and strong commitment to safety and health in the workplace. Toward this end, management must monitor company safety and health performance, and also work environment and conditions to ensure that program objectives are achieved.

- Our safety program applies to all employees and persons affected or associated in any way by the scope of this business. Everyone’s goal must be to constantly improve safety awareness and to prevent accidents and injuries.

Everyone at Brenman Company must be involved and committed to safety. This must be a team effort. Together, we can prevent accidents and injuries. Together, we can keep each other safe and healthy in the workplace.

Manual de seguridad para

empleados de la construcción

Brenman Company

Una guía para empleados sobre políticas y procedimientos de seguridad

a fin de respaldar la conciencia sobre la seguridad en el entorno de trabajo

Provista por: Associates Insurance Agency

Descargo de responsabilidad para los usuarios de este manual para empleados con formulario: Los documentos se presentan con fines de referencia general solamente. Las leyes federales, estatales o locales, o las circunstancias individuales, pueden requerir la adición de políticas, la enmienda de políticas individuales y/o del Manual en su totalidad para adecuarse a situaciones específicas. Estos documentos deben utilizarse sólo como pautas y no deben utilizarse, adoptarse o modificarse sin la orientación de un asesor jurídico competente. Por lo tanto, estos documentos se presentan sabiendo que la Compañía no se ocupa de prestar servicios legales, contables ni ningún otro tipo de servicio profesional. Si se requiere el asesoramiento jurídico o la asistencia de otro especialista, se debe buscar la asistencia de un profesional competente.

Compromiso con la seguridad

En Brenman Company reconocemos que nuestros empleados son el motor de nuestra compañía. Como recurso fundamental, protegeremos a nuestros empleados a través de la capacitación, la provisión de entornos laborales adecuados y procedimientos que promueven la protección de la salud y la seguridad. Todas las tareas realizadas por los empleados de Brenman Company deberán contemplar el objetivo de esta política. Ninguna función, sin importar su resultado visible, será considerada más importante que la salud y la seguridad del empleado.

En Brenman Company estamos firmemente comprometidos con la seguridad de nuestros empleados. Haremos todo lo posible para prevenir accidentes en el lugar de trabajo y estamos comprometidos a brindar un entorno laboral seguro para todos los empleados.

Valoramos a nuestros empleados no sólo como trabajadores sino también como seres humanos fundamentales para el éxito de su familia, la comunidad local y Brenman Company.

Se alienta a los empleados a comunicar cualquier práctica no segura o riesgos de seguridad existentes en el lugar de trabajo. Se deben comunicar de inmediato todos los accidentes/incidentes (sin importar su insignificancia) al supervisor de guardia.

Un factor clave en la implementación de esta política será el cumplimiento riguroso de todas las políticas y los procedimientos federales, estatales, locales aplicables y aquéllos de la compañía. El incumplimiento de estas políticas puede acarrear medidas disciplinarias.

En relación con esto, Brenman Company hará todo lo posible para facilitar un lugar de trabajo seguro y saludable sin riesgos posibles reconocidos o conocidos. Además, Brenman Company está de acuerdo con estos principios:

- Todos los accidentes pueden prevenirse a través de la implementación de las políticas y los programas eficaces de Control de salud y seguridad.

- Los controles de salud y seguridad son una parte fundamental de nuestro trabajo diario.

- La prevención de accidentes es una empresa rentable. Minimiza el sufrimiento humano, promueve mejores condiciones laborales para todos, contribuye a formar una buena opinión de Brenman Company entre los clientes e incrementa la productividad. Es por esto que Brenman Company obedecerá todas las reglamentaciones sobre salud y seguridad que se aplican al curso y campo de acción de las operaciones.

- La Gerencia es responsable de facilitar el lugar de trabajo más seguro posible para los Empleados. En consecuencia, la gerencia de Brenman Company se compromete a asignar y brindar todos los recursos necesarios a fin de promover e implementar esta política de seguridad en forma eficaz.

- Los empleados son responsables de seguir las prácticas seguras en el trabajo y las reglas de la compañía, y de prevenir accidentes y lesiones. La gerencia establecerá líneas de comunicación para solicitar y recibir comentarios, información, sugerencias y asistencia de los empleados en lo que respecta a la salud y la seguridad.

- La gerencia y los supervisores de Brenman Company establecerán dignos ejemplos a través de buenas actitudes y un fuerte compromiso con la seguridad y la salud en el lugar de trabajo. Con este fin, la Gerencia debe supervisar el desempeño de la compañía en materia de seguridad y salud, y el entorno y las condiciones en el lugar de trabajo a fin de garantizar el cumplimiento de los objetivos de sus programas.

- Nuestro programa de seguridad se aplica a todos los empleados y personas afectadas o asociadas de cualquier forma con el campo de acción de esta compañía. El objetivo de todos debe ser mejorar la conciencia sobre seguridad y prevenir accidentes y lesiones en forma constante.

Todas las personas en Brenman Company deben participar y comprometerse con la seguridad. Ésta debe ser una iniciativa conjunta. Juntos, podemos prevenir los accidentes y las lesiones. Juntos, podemos ayudarnos mutuamente a gozar de un lugar de trabajo seguro y saludable que nos brinda nuestro sustento.

Fall Protection Program

REFERENCE STANDARD

This procedure is developed in accordance with provisions as outlined in the OSHA safety standards for General Industry (Part 1910), Subpart D: Walking and Working Surfaces, specifically 29 CFR 1910.21 – Definitions; 29 CFR 1910.22 – General Requirements; 29 CFR 1910.23 – Guarding Floor & Wall Openings and Holes; and 29 CFR 1910.24 – Fixed Industrial Stairs.

PURPOSE

This policy establishes how Brenman Company will enhance safe working conditions at this facility through the establishment of specific walking and working surface requirements and protection from fall hazards.

SCOPE

This policy applies to all Brenman Company employees and all company contractors, visitors or vendors.

RESPONSIBILITIES

Senior management will:

- Require the full application and integration of this policy into daily operations, as applicable, in all areas of responsibility and with all direct reports;

- Assess managers and supervisors on their ability to apply this policy in their areas of responsibility; and

- Provide fall protection to affected employees.

The Safety Administrator will administer all aspects of this policy to include:

- Maintaining and updating the written program as required;

- Coordinating necessary training for all affected employees;

- Providing necessary technical assistance to managers and supervisors; and

- Periodically assessing the effectiveness of this program and its implementation in all affected areas of the company.

Managers and supervisors will:

- Know how this policy applies to those under their direct control;

- Integrate and enforce the provisions of this policy in their areas of responsibility;

- Periodically audit the effectiveness of this policy in their areas of responsibility;

- Coordinate training for all affected employees;

- Provide appropriate coaching and corrective action when necessary to ensure this policy is fully integrated; and

- Investigate and document all incidents that result in employee injury.

All affected employees will:

- Integrate the provisions of this policy into their daily activities as applicable;

- Follow all training, instructions and directives relative to this policy;

- Seek clarification whenever there are questions concerning the application of this policy into daily operations;

Policy

Return to Work

PURPOSE

This policy is in place to ensure Brenman Company provides meaningful work activity for employees who are temporarily unable to perform all, or portions, of their regular work assignments or duties. This policy applies to employees suffering from either work or non-work related injury or illness. The goal is to allow valued company employees to return to productive, regular work as quickly as possible. By providing temporary transitional or modified work activity, injured employees remain an active and vital part of the company. Studies show that a well-constructed Return to Work Policy reduces lost time days, allows workers to recover more quickly and makes for a more positive work environment.

SCOPE

All active employees who become temporarily unable to perform their regular job due to a compensable work related or non-work related injury or illness may be eligible for transitory work duties within the provisions of this program. Return to work tasks may be in the form of:

- Changed duties within the scope of the employee’s current position

- Other available jobs for which the employee qualifies outside the scope of his or her current position

- An altered schedule of work hours

DEFINITIONS

- Transitional duty is a therapeutic tool used to accelerate injured employees’ return to work by addressing the physical, emotional, attitudinal and environmental factors that otherwise inhibit a prompt return to work. These assignments are meant to be temporary and may not last longer than 90 days, though Brenman Company permits multiple 90-day assignments back-to-back if it is medically warranted.

- Alternate duty is a part of Brenman Company’s Return to Work Policy that is designed as a placement service for individuals who have reached maximum medical improvement and are still unable to perform the essential functions of their pre-injury job.

APPLICABILITY

Length of Duty

- If work is available that meets the limitations or restrictions set forth by the employee’s attending practitioner, that employee may be assigned transitional or modified work for a period not to exceed 90 days. Transitional or light duty is a temporary program, and an employee’s eligibility in these reduced assignments will be based strictly on medical documentation and recovery progress.

Daily Application

- An employee’s limitations and restrictions are effective 24 hours a day. Any employee who fails to follow his or her restrictions may cause a delay in healing or may further aggravate the condition. Employees who disregard their established restrictions, whether they are at work or not, may be subject to disciplinary action up to and including termination.

Qualification

Transitional or modified duty will be available to all employees on a fair and equitable basis with temporary assignments based on skill and abilities. Eligibility will be based upon completion of the Return to Work Evaluation Form by the

Alternate Ideas for Return to Work Duties

Construction

Use this chart to find possible transitional job duties for recovering workers. The ideas presented here should be adapted to your own situation to help the returning employee be as productive as possible. Always evaluate the unique conditions of an employee’s injury when assigning transitional duties.

| Type of Injury | |||

| Alternative Duty Options | Back | Lower Extremity | Upper Extremity |

| Comparison shopper (are suppliers providing best product/prices, what are competitors’ prices/services) | Yes | Yes | Yes |

| Designer assistant | Yes | Yes | Possible |

| Fall-protection equipment inspector | Yes | Yes | Yes |

| Gate attendant/site security | Yes | Yes | Yes |

| Heavy-equipment inspector | Possible | Possible | Yes |

| MSDS book updater/organizer | Yes | Yes | Possible |

| Power tool inspector/inventory taker/minor maintenance | Yes | Yes | Possible |

| Pre-shift prep (arrive prior to shift start, have all tools and equipment out and ready to go) | Possible | Possible | Possible |

| Quality control inspector | Yes | Yes | Yes |

| Site clean-up (put tools away, clear debris) | Possible | No | Possible |

| Site housekeeping (magnet sweep, pick up debris, organize job trailer/tool trailer) | No | Possible | Possible |

| Superintendent/manager assistant | Possible | Possible | Possible |

| Take company vehicles to service shop (oil change, tire rotation, etc.) | Possible | Possible | Yes |

| Tool sharpener or tool and property engraver | Possible | Yes | No |

| Traffic flagger (if certified, qualified) | Possible | Possible | Possible |

| Vehicle/equipment washer | Possible | Possible | Possible |

| Water tank truck driver | Possible | Possible | Yes |

| Attend vendor-provided specialty or recurring training | Yes | Yes | Yes |

| Cross trainer/mentor | Yes | Yes | Yes |

| Conduct customer opinion surveys (via telephone) | Yes | Yes | Yes |

| Develop safety training schedule, identify and schedule topics/trainers | Yes | Yes | Yes |

| Foreign language translator (translate policies/practices/posters to other common language) | Yes | Yes | No |

| Mail/fax delivery for small packages | Possible | Possible | Yes |

| Research laws/regulations pertaining to industry | Yes | Yes | Yes |

| Review and evaluate safety training videos, recommend those to use for staff training | Yes | Yes | Yes |

OSHA 300 Recordable Incident Advisor

OSHA 300 Recordable Incident Advisor

Builder’s Risk Coverage: Understanding the Policy Period

Construction projects, regardless of their size, can present complex insurance issues. Are you confused about your exposures and policy options? If so, it’s no surprise—there are no standard builder’s risk policy forms covering these types of risks. To help you limit your exposure, here are some helpful builder’s risk policy basics.

The Basics

Builder’s Risk coverage is a type of property insurance specifically designed to cover property during the course of construction, including renovation and repair. Why do you need it? There are additional risks and responsibilities inherent in this type of work that a typical property policy is not designed to cover. For example, if someone steals contractors’ equipment from the job site or if construction materials are damaged, you could be liable for the loss if you do not have builder’s risk coverage.

Typically the coverage is purchased by either the property owner or contractor.

Regardless who purchases the coverage, all parties that have property involved in the project should be named in the policy. This may include the owner, contractor, subcontractors, the financial institution funding the project, and, in some cases, the architects and engineers. Once the project is completed and/or accepted by the owner, your regular property policy kicks in.

Since builder’s risk coverage only deals with the property, it does not include coverage for worksite injuries or design/construction defects. For any mishaps that occur on the job, you should rely on liability and workers’ compensation insurance policies for coverage.

Policy Period

When purchasing builder’s risk coverage, one of the issues often overlooked is the policy period – it may not be clear when the coverage begins and ends. As a result, keep the following in mind:

Commencement of Coverage: Builder’s Risk policies provide coverage for property in the course of construction, renovation or repair. But at what point does construction renovation or repair begin?

- Typically, contracts require that insurance be provided for the duration of the contract period. This means that the policy inception date would be the date the contracts are signed.

- The lender may also specify the inception date.

- However, be sure to review insurance policy

A Word to the Wise about Construction Defects: What You Can Do to Protect Your Business

Possibly no two words strike more fear in the hearts of architects, engineers and contractors than “construction defect.” A claim for construction defect can cost astronomical amounts to correct and defend. And then there’s the damage to your reputation and its impact on your future opportunities for work. It’s enough to break a business.

Construction Defect Risks

Today, your risk of becoming involved in a construction defect claim is greater than ever. New technology, materials and applications have changed the way commercial buildings, homes and condominiums are constructed.

Advances are enabling the design and construction of buildings that are more attractive and less costly. Yet, many of these advances have yet to be tested in real application over time, where problems may be uncovered that were never anticipated in the lab.

At the same time, new applications require new skills from contractors, who may overlook important requirements for installation or take shortcuts that cause devastating consequences. When problems occur, it’s hard to know the cause without investigation, and everyone on the project is forced to become involved. Fingers point. Often, whoever has the deepest pockets or the most to lose becomes the primary target for plaintiff lawyers. Fairly or not, you could be left holding the bag for others’ mistakes.

Let’s consider two of the most costly recent examples of construction defect, EIFS and FRT plywood:

EIFS

Architects love to design using EIFS (exterior insulation finishing systems.) EIFS cladding systems resemble stucco, but are less costly to install and can be fashioned into a variety of architectural shapes, including soft curves and geometric designs. This unique flexibility makes EIFS treatments ideal for special elements such as porticos, archways, ornate overheads for windows, doors and decorative trim.

Today, your risk of becoming involved in a construction defect claim is greater than ever with new technology, materials and applications changing the way we construct buildings.

As with any exterior cladding, water can enter behind or around the system. Early applications often lacked drainage features more commonly used today. With no place to go, constant exposure to moisture can cause rot in wood and damage to other materials within th

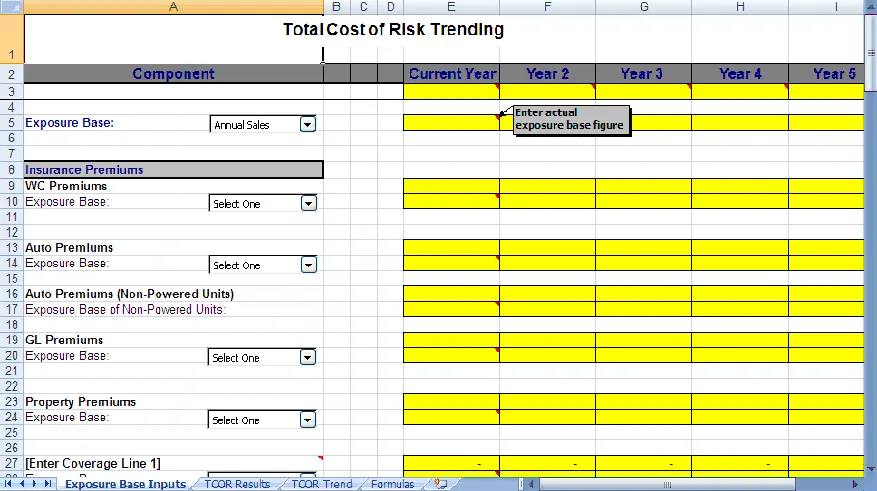

Total Cost of Risk Trending Worksheet

OSHA Safety Cornerstones Newsletter

A newsletter of practical compliance and safety tips provided by Associates Insurance Agency

IN THIS ISSUE

Top 10 Most Frequently Cited OSHA Standards for 2014

New Whistleblower Rule Implemented

OSHA Proposes Revisions to Eye and Face Standards

Information on OSHA’s 2015 Fall Safety Stand-Down

OSHA Clarifies Definition of “Amputation”

OSHA Reporting and Kinesiology Tape

Top 10 Most Frequently Cited OSHA Standards for Fiscal Year 2014

OSHA has released results from inspections conducted during the 2014 fiscal year (Oct. 1, 2013, through Sept. 30, 2014). The following list shows the most frequently cited OSHA standards during that time period:

- 1926.501 – Fall Protection (construction standard)

- 1910.1200 – Hazard Communication

- 1926.451 – Scaffolding (construction standard)

- 1910.134 – Respiratory Protection

- 1910.178 – Powered Industrial Trucks

- 1910.147 – Lockout/Tagout

- 1926.1053 – Ladders (construction standard)

- 1910.305 – Electrical, Wiring Methods

- 1910.212 – Machine Guarding

- 1910.303 – Electrical, General Requirements

What are the practical applications of OSHA inspection data for employers?

In theory, every OSHA inspection is an independent event, with the results of one inspection having no bearing on an inspection at another location. In practice, however, this is not how inspections typically work. Similar to how you might have specific benchmarks or metrics that you focus your attention on at your workplace, OSHA inspectors often receive guidance on which standards they should give extra scrutiny to during inspections. Given a large enough sample size, these points of emphasis can be discerned based upon the frequency with which the standard is cited by inspectors.

Although the overall composite data for all employers is a useful starting point, to get an accurate picture of what inspectors are focusing on in your industry, we recommend that you conduct a search of frequently cited OSHA standards for your industry segment. The following link will allow you to view inspection results by NAICS code and number of employees: https://www.osha.gov/pls/imis/citedstandard.html.

New Whistleblower Rule Implemented; DOL Emphasis on Retaliation Continues

Perhaps the single defining characteristic of the Obama-era Department of Labor has been its unprecedented emphasis on vigorously prosecuting whistleblower retaliation claims. In recent years, we’ve witnessed not only a record number of whistleblower-related lawsuits but a steep escalation in the size of the penalties associated with these lawsuits.

On March 5, 2015, OSHA published a final rule codifying the procedures for handling whistleblower retaliation claims under the Sarbanes-Oxley Act (SOX). SOX prohibits publicly traded companies (and their subsidiaries), nationally recognized statistical ratings organizations and other covered individuals from retaliating against any employee who reports an activity reasonably believed to be fraud under mailing, wiring, banking or securities laws.

The final rule went into effect on March 5, 2015, replacing the interim final rule that was issued in 2011. Under the final rule, whistleblowers have 180 days from the date of retaliation to file a complaint with OSHA. In the complaint, the whistleblowing employee must show that he or she suffered adverse employment action and that protected activity was a contributing factor of the adverse employment action. After receiving a complaint, OSHA will notify the affected employer that a complaint has been filed. OSHA will also provide the employer with the allegations and the substance of the evidence that supports the complaint (subject to privacy and confidentiality laws). The employer will then have a chance to show by clear and convincing evidence that it would have taken the same action, regardless of the protected activity. OSHA will begin an investigation if the employer fails to show clear and convincing evidence.

OSHA Proposes Revisions to Eye and Face Standards

OSHA recently published a proposal to revise personal protective equipment requirements in the agency’s general industry, shipyard employment, longshoring, marine terminals and construction standards. The proposal, if enacted, would align OSHA’s eye and face protection standard with the latest ANSI consensus standards on eye and face protection. OSHA also plans to update the construction eye and face protection standard to make it more consistent with general industry and maritime standards.

2015 Fall Safety Stand-Down

Building on its unprecedented participation from last year’s event, OSHA has announced this year’s Fall Safety Stand-Down to prevent falls in construction, scheduled for May 4 through 15, 2015. Last year, tens of thousands of employers and more than 1 million workers across the country joined OSHA in a week-long construction Fall Safety Stand-Down, the largest occupational safety event ever hosted in the United States. Click here for more information on this year’s event.

OSHA Clarifies “Amputation” Definition

OSHA recently issued guidance clarifying new reporting requirements for amputations. Under OSHA guidelines, amputations are defined as the “traumatic loss of a limb or other external body part.”

Amputations include fingertips (with or without bone loss), medical amputations caused by irreparable damage and amputations of body parts that had previously been reattached. Amputations do not include avulsions, enucleations, deglovings, scalpings, severed ears, broken or chipped teeth, or the removal of fingernails, toenails or eyelids.

Employers should rely on medical diagnoses to determine the classification of an injury, and, if necessary, report it as an amputation. If no diagnosis is available, employers should rely on the definitions and examples of amputations set forth in the regulatory text.

OSHA Reporting and Kinesiology Tape

In a recent letter of interpretation (LOI), OSHA clarified that when kinesiology tape is used to treat a work-related injury, the injury is considered recordable for OSHA recordkeeping purposes. Developed in the 1970s, kinesiology tape is a thin, stretchy band of adhesive material. Intended to treat musculoskeletal injuries and inflammatory conditions, OSHA determined that the use of kinesiology tape is akin to physical therapy and is considered medical treatment beyond first aid for OSHA recordkeeping purposes.

© 2015 Zywave, Inc. This publication is for informational purposes only. It is not intended to be exhaustive nor should any discussion or opinions be construed as compliance or legal advice.

Risk management tips brought to you by:Associates Insurance Agency

DID YOU KNOW?

The U.S. Attorney recently filed charges against James J. McCullagh, the owner of a roofing company, related to the fatal fall of one of his employees.

The indictment alleges that McCullagh failed to provide his employee with proper safety equipment including a safety harness, lied to OSHA investigators about the incident and told his other employees to corroborate his lies.

If convicted, McCullagh could face 25 years in prison and $1.5 million in fines.

OSHA Issues Final Rule for Construction in Confined Spaces

Young Hispanic immigrants working for small construction companies face an especially high risk of workplace injury or death, according to a new report released by the American Society of Safety Engineers (ASSE) and the National Institute of Occupational Safety and Health (NIOSH).

The report describes the main reasons for that demographic’s vulnerabilities:

- Hispanic immigrants often suffer from language barriers

- Young workers under the age of 25 lack sufficient training or experience

- Small companies often lack safety personnel or resources to adequately address risks

The report identifies some possible interventions—specifically suggesting collaborative efforts with outside groups like safety organizations, community groups and Latin American consulates—that could help fill in the gaps and provide vital supplemental safety training for employees.

While they highlight some possible interventions, NIOSH and ASSE view their report as a first step—one that they hope will help them to develop even better strategies for promoting workplace safety.

ANSI Standard May Not Protect Workers

NIOSH recently warned that the American National Standards Institute (ANSI) released a revision of its standard on nail guns that failed to take into account NIOSH input and current scientific research. As a result, NIOSH warns, the ANSI standard may not sufficiently protect workers from the dangers of nail guns. NIOSH encourages employers and workers to refer to NIOSH publications for the most effective recommendations regarding nail gun safety. Nail Gun Safety: A Guide for Construction Contractors and Straight Talk About Nail Gun Safety are both available online for free in both English and Spanish.

| For: Brenman Company | Project #: |

| Project Manager: | Site Manager: |

| Jobsite Address: |

| REQUIRED? | PROVIDED / PERFORMED BY OWNER? | PROVIDED / PERFORMED BY VENDOR? | DONE? | |

| Are any permits required? If so, date and which applied for: | ||||

| Is a field office ordered? | ||||

| Is a telephone installed? Has the number been given to the main office? | ||||

| Is a project sign ordered? |

Comments:

| REQUIRED? | PROVIDED / PERFORMED BY OWNER? | PROVIDED / PERFORMED BY VENDOR? | DONE? | |

| Has power been hooked up? | ||||

| Is a fax machine set up? | ||||

| Has a rubbish removal service been ordered? | ||||

| Have temporary toilets been ordered? | ||||

| Has a surveyor been hired? | ||||

| Is a testing service hired? | ||||

| Has the post office been notified and the address established? | ||||

| Has a drinking water service been provided? | ||||

| Have communication radios been provided? |

Comments:

| REQUIRED? | PROVIDED / PERFORMED BY OWNER? | PROVIDED / PERFORMED BY VENDOR? | DONE? | |

Are OSHA & Labor Law posters hung? State specific postings? | ||||

| Is a first aid kit provided? | ||||

| Is the emergency telephone list posted? | ||||

| Have EPA issues been identified? | ||||

| Reference Books on site: Safety Policy Handbook, SDS, Tool Box Safety Talks? | ||||

| Employee Safety Handbooks distributed? Sign pages filed? | ||||

| Have specific job hazards been analyzed and identified? | ||||

| Is special training required? | ||||

| Is there a sufficient supply of hard hats & safety glasses? | ||||

| Are fire extinguishers and a servicing vendor available? | ||||

| Are safety belts provided? | ||||

| Are lockout tags/locks provided? | ||||

| Equipment guards checked and in place? | ||||

| Personal Protective Equipment identified and issued? | ||||

| Welding or open flame permits on site? | ||||

| Equipment maintenance vendor identified? |

Comments:

| General OSHA Requirements | COMPLETED |

| Each employee on a scaffold more than 10 feet above a lower level must be protected from falling to that lower level. | |

| Fall protection consists of either personal fall arrest systems or guardrail systems meeting OSHA requirements. | |

| OSHA requires that scaffolds are to be erected, moved, dismantled or altered only under the supervision of a competent person that is qualified in such activities. | |

| OSHA requires scaffolds over 125 feet in height and rolling scaffolds over 60 feet in height must be designed by a registered professional engineer, and constructed and loaded in accordance with such design. | |

| Employees performing overhand bricklaying operations from a supported scaffold must be protected from falling from all open sides and ends of the scaffold, except at the side next to the wall being laid. |

| Setup | COMPLETED |

| The scaffold must be erected under the direction of a competent person(s). | |

| Employees involved with set up (or near) the scaffold must wear hard hats. | |

| Scaffold should be level, and footings should be sound and rigid. Do not set footings on soft or frozen ground (that could melt), or on blocks. | |

| The front face of the scaffolding must be set up within 14 inches of the work (or within 3 feet for outrigger scaffolds). | |

| Verify the minimum top edge height on the scaffold is at least 38 inches, but not more than 45 inches. Each top rail needs to withstand a force of at least 200 pounds. | |

| Verify the capacity—the scaffold must to able to hold four times its maximum intended load. | |

| The platform should be complete from front to back and side to side. It must be fully planked or decked, with no gaps greater than 1 inch. | |

| Provide guardrails and toe boards on all open sides. | |

| When erection is completed, wheels and/or castors should be in a locked position. | |

| Ensure all sections are pinned or appropriately secured. | |

| Provide a safe way for workers to get on and off the scaffold (without climbing on cross braces), such as a ladder. | |

| Scaffold must meet electrical safety clearance distances (no overhead obstructions or electric lines within 12 feet of the scaffold assembly). |

| Training and Use | COMPLETED |

| Provide training by a competent person to all employees involved in erecting, dismantling, repairing, inspectingand/or working on scaffolds. Training should focus on training workers to recognize the hazards associated with scaffolding activities. | |

| Require employees to inspect the scaffolding before each work shift. | |

| Hardhats must be worn by workers on and around the scaffold. | |

| Verify scaffold loads, including tools and other equipment, are kept to a minimum and materials are removed when the scaffold is not in use. | |

| Ensure employees are removed from scaffolds during high winds or bad weather. | |

| Before moving a scaffold, secure all materials and vacate workers from the platform. | |

| Hoist up all heavy tools, equipment, supplies, etc., rather than carry up by hand. |

| Fall Protection — Fall-Arrest Systems | COMPLETED |

| In addition to meeting general scaffolding requirements, personal fall-arrest systems used on scaffolds must be attached by lanyard to a vertical lifeline, horizontal lifeline or scaffold structural member. When vertical lifelines are used, they must be fastened to a fixed safe point of anchorage, independent of the scaffold, and be protected from sharp edges and abrasion. Safe points of anchorage include structural members of buildings, but not standpipes, vents, electrical conduit, etc., which may give way under the force of a fall. Be aware that it is dangerous and therefore impermissible for two or more vertical lifelines to be attached to each other, or to the same point of anchorage. When horizontal lifelines are used, ensure they are secured to two or more structural members of the scaffold. |

Source: OSHA Safety and Health Regulations for Construction, Standard 1926.451

| To avoid slips and falls, be on the lookout for hazards such as water, grease, cables, sawdust, paint or other construction site debris. |

Avoiding Slips and Falls at the Site

On any given day, the injury rate for construction workers is higher than the national average for all other industries. Following these basic slip and fall prevention tips can help prevent you from becoming a statistic.

Do Your Safety Part

There are various ways to suffer slips and falls while working. You can slip and lose your balance, trip over objects left improperly in a walkway or fall from a ladder or scaffolding. To avoid these mishaps, be on the lookout for tripping hazards such as:

· Water puddles

· Worksite materials

· Grease or oil

· Sawdust

· Extension cords and cables

Even small quantities are enough to make you fall.

Good Housekeeping Counts

When entering a building from the outdoors or from debris areas, clean your footwear thoroughly. Snowy and rainy weather require a doormat at each entrance to allow for complete wiping of shoes.

Beware of tripping hazards—trash, unused materials or any object left in walkways invites falls. Extension cords, tools, carts and other items should be removed or properly barricaded off. If equipment or supplies are left in walkways, report it. Let the proper personnel remove it. And keep passageways clean of debris by using trash barrels and recycling bins.

Practice Prevention

Walk in designated walking areas. Concentrate on where you are going—horseplay or short cuts through the job site invites accidents. If you’re carrying a heavy load that hampers your ability to see properly, request spotting assistance from a co-worker.

The worst falls are from elevated positions such as ladders, and can result in serious injury or death. Learn and practice ladder safety and the proper use of scaffolding. For example, when climbing, use a ladder of proper length that is in good condition. Keep it placed on a firm surface. Do not climb a ladder placed on machinery, crates, stock or boxes. Keep the ladder’s base one foot away from the wall for every four feet of height. Don’t over-reach. Always have control of your balance when working from a ladder. Never climb a ladder with your hands full, and always transport tools in their proper carrying devices.

When using scaffolding, be sure it is properly assembled according to the manufacturer’s specifications. Check carefully for defects. Standing and working planks should be level and clean. Use toe boards to prevent tools from falling and workers from slipping. Report any misuse of proper scaffolding safety.

Slips and falls occur every day. The extent of injuries and their recurrence can be minimized through proper safety knowledge, good housekeeping and practicing prevention.

To avoid slips and falls, be on the lookout for hazards such as water, grease, cables, sawdust, paint or other construction site debris.

Take your duty of being a safe construction site worker seriously. Answer the following questions to determine your level of general construction protection safety.

- Guardrail systems or personal fall arrest systems must be used when working on surfaces with unprotected edges that are how many feet above a lower level, according to OSHA standards?

- 4 feet

- 6 feet

- 8 feet

- 10 feet

- Which of these methods is not considered safe fall protection when working near a hole?

- Guardrail system

- Cover

- Personal fall arrest system

- Warning line system

- Posts placed for wood, pipe or structured steel guardrails are to be spaced no more than how many feet apart on the centers?

- 6 feet

- 8 feet

- 12 feet

- 16 feet

- How many feet should a worker be able to free fall when using a body belt or harness as part of a positioning device system?

- 2 feet

- 3 feet

- 4 feet

- 5 feet

Playing it Safe

Be safe and healthy on the job at Brenman Company with these helpful tips provided by Associates Insurance Agency

| Be safe and healthy on the job at Brenman Company with these helpful tips provided by Associates Insurance Agency |

Top Four Construction Hazards

Do you know the risks?

You’re good at your job and you love what you do. However, every time you come to work, you risk suffering an injury. The construction site is one of the most hazardous workplaces, and many of the injuries that occur there are caused by these top four hazards: falls, struck-by, caught-in/between and electrocutions.

When you have sufficient knowledge, preventing accidents caused by these hazards is easier than you might think. Here are some basic safety tips to keep you injury-free.

Preventing Falls

- Wear and use fall arrest equipment.

- Install and maintain perimeter protection.

- Cover and secure all floor openings and label floor opening covers.

- Use ladders and scaffolds safely.

Preventing Struck-bys

- Never position yourself between moving and fixed objects.

- Wear high-visibility clothes near equipment and vehicles so that others can see you clearly.

Preventing Caught-in-between Hazards

- Never enter an unprotected trench or excavation that is five feet or deeper without an adequate protective system in place. (Note: some trenches that are less than five feet may need a similar system as well.)

- Make sure that a trench or excavation is protected either by sloping, shoring, benching or a trench shield systems.

Preventing Electrocutions

- Locate and identify utilities before starting work for the day.

- Look for overhead power lines when operating any equipment.

- Maintain a safe distance away from power lines and learn your area’s distance requirements.

- Do not operate portable electric tools unless they are grounded or double-insulated.

- Use ground-fault circuit interrupters for protection.

- Be alert to electrical hazards when working with ladders, scaffolds or other platforms.

The List Goes On

Though these top four hazards are the most common on construction sites, you are exposed to many more dangers on a daily basis. To remain safe, be an active participant in all safety initiatives and trainings at Brenman Company and keep safety at the top of your mind every day.

Mantenga tres puntos de contacto para evitar caídas

Subir o bajar de un camión o equipo de gran tamaño sin sufrir heridas parece simple, pero muchos accidentes implican este tipo de lesiones. La mejor forma de evitar caídas al subir o descender de un camión, cabina de tractor o equipo pesado es respetar el sistema de tres puntos de contacto.

Sistema de tres puntos de contacto

Tres puntos de contacto es exactamente eso: tres de las cuatro extremidades están en contacto con el vehículo en todo momento. Puede ser dos manos y un pie, o dos pies y una mano.

Independientemente del tipo de sistema de acceso que tenga disponible su vehículo o equipo, el sistema de tres puntos reducirá significativamente las posibilidades de deslizamientos o caídas, ya que permite mantener la estabilidad y el apoyo máximos al entrar o salir de un equipo. Los tres puntos forman un triángulo, lo que distribuye el peso del cuerpo hacia el centro.

Recuerde, la única persona que puede evitar caídas es usted. A continuación se describen algunas cosas que se deben y no se deben hacer al entrar o salir de un vehículo grande u otro equipo de construcción para evitar lesiones.

Qué se debe hacer

· Siempre salga y entre al vehículo de frente a la cabina.

· No se apresure y tenga extremada precaución en las condiciones climáticas adversas.

· Tómese bien de las barandas o manijas.

· Use las partes diseñadas por el fabricante para subir o bajar. Esto incluye los escalones, los estribos, las bandas de extensión, los pedestales, las empuñaduras, etc.

· Antes de salir, observe que en el suelo no haya obstáculos.

· Use calzado seguro antideslizante con buen apoyo.

· Limpie sus zapatos; el lodo, la grasa y el aceite pueden producir resbalones.

· Inspeccione que las barandillas, las escaleras y los peldaños estén en buenas condiciones.

· Sólo suba o baje del equipo cuando esté inmóvil.

Lo que no debe hacer

· Nunca porte un objeto con la mano que tiene libre al subir o bajar de un equipo. Coloque el objeto en el piso del vehículo y tómelo cuando haya bajado.

· No se apresure a bajar del vehículo o maquinaria después de estar mucho tiempo sentado. Baje lentamente para evitar la tensión muscular o la pérdida del equilibrio.

· Nunca salte de un equipo de construcción o vehículos. Puede perder el equilibrio o puede aterrizar sobre una superficie despareja y caerse. No use neumáticos, ejes de ruedas o los rieles de máquinas como superficie de apoyo.

La mejor forma de evitar caídas al subir o descender de un camión u otro equipo de construcción es respetar el sistema de tres puntos de contacto.